HDF/MDF HOMADUR® Raw

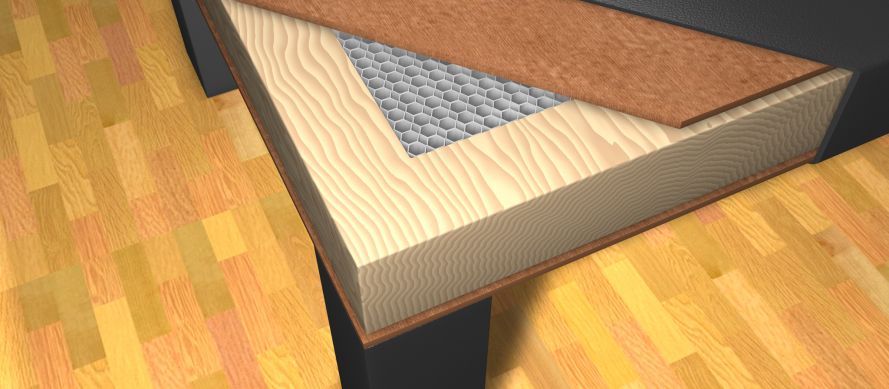

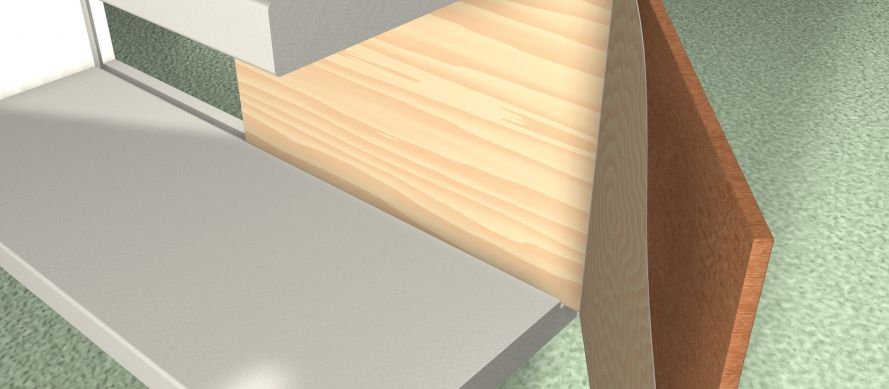

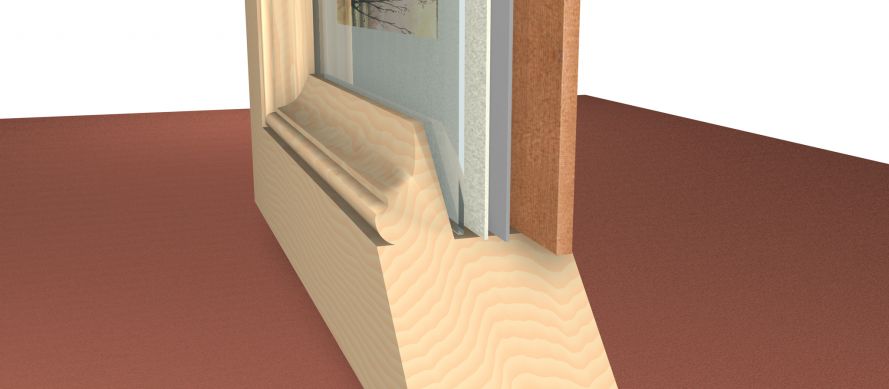

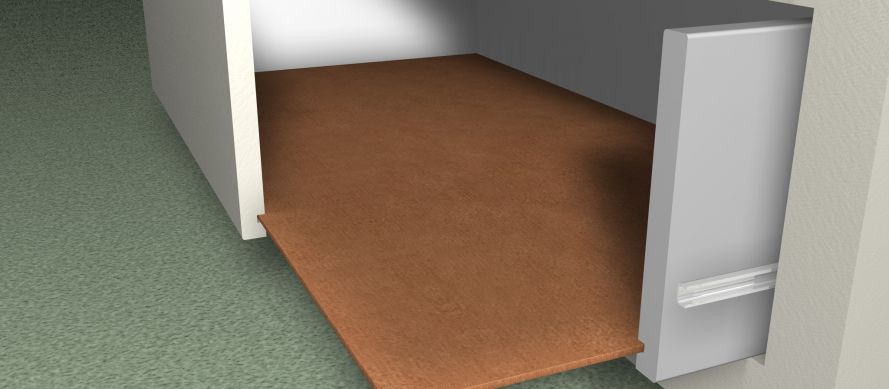

HDF/MDF HOMADUR® Raw wood fibreboards have ideal properties that make them the perfect choice for a wide range of applications. They can be supplied with both faces sanded ready for further processing. We also manufacture HDF HOMADUR® Raw Flame Retardant B1 wood fibreboard, HDF HOMADUR® Coreboard for Flooring.

standard quality

Strengths

- Dense, smooth and hard surface

- Excellent dimensional stability

- Exceptionally flat

Face/Back

unsanded – both sides smooth or sanded on one or both sides

Thicknesses

1.5 - 10.0 mm - various thicknesses upon request

Formats

2440 x 1220 mm

3050 x 1220 mm

2650 x 2070 mm

2800 x 2070 mm

5300 x 2070 mm

3050 x 2440 mm

Special formats and cut to sizes upon request

Processing

HDF/MDF HOMADUR® Raw fibreboards can be finished in various ways using suitable techniques. Further processing can be carried out using standard woodworking machinery and tools. You must carry out your own trials and tests in advance.

Environment

The environmental compatibility of the HDF/MDF HOMADUR® Raw wood fibreboards begins with the environmentally-friendly materials used, such as untreated timber and low-formaldehyde binding agents, and ends with our innovatively ecological and gentle manufacturing process. Thermal utilisation HDF/MDF HOMADUR® Raw wood fibreboards is harmless to the environment.