HDF HOMADUR® Alu-Climate and Radiation Protection Door Skins

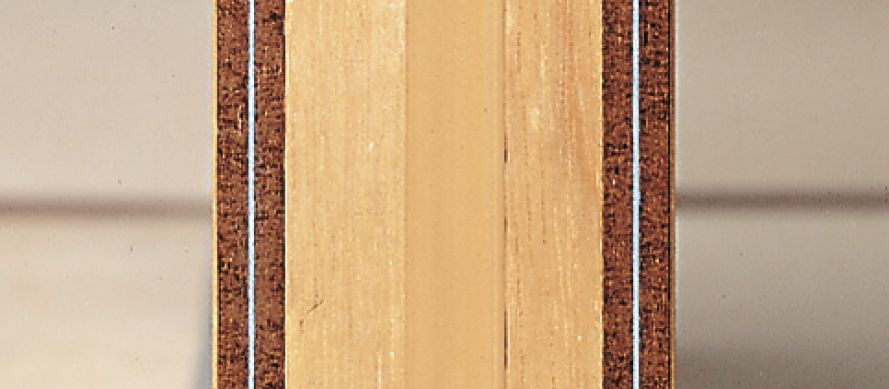

For doors that need to comply with climate class III, the HDF HOMADUR® fibreboards are produced with a special aluminium inlay at their core. This acts as a moisture barrier and gives the A lu-Climate door excellent bending strength and dimensional stability. The requirements for radiation protection doors – for x-ray rooms, for example – are met by including an inlay made of lead. The HDF HOMADUR® Alu-Climate and Radiation Protection Door Skins are available in standard door sizes.

standard quality

Strengths

- High inherent stability

- Ideally suited to surface finishing

- Stress-free composite element, therefore absolutely flat

- Fire and burglar retardant

Also radiation resistant, in the case of HDF HOMADUR®

- Radiation Protection Door Skins: the lead equivalent value is according to D IN 6812. The above-mentioned standard requires that the planners and the x-ray equipment manufacturer prepare a radiation protection plan, which must be used as the basis for all protective measures.

Processing

After longer periods of storage at low temperatures and in humid conditions, HDF HOMADUR® Alu-Climate Door

Skins must first be allowed to acclimatise for at least 24 hours in the production hall before the pressing process

commences. This also applies to HDF HOMADUR® Radiation Protection Door Skins. When processing the fibreboards, the temperature of the boards should be 15 °C or higher. For HDF HOMADUR ® Radiation Protection Doors, the following must be observed in addition: Before any further processing, such as edge-planing or profiling, is carried out, the finished door blank should rest for at least 24 hours or at least be cooled down using a star cooler, for example.